We throw away around 2,000,000 pans every year in Switzerland

However, 87% of the pans – apart from their non-stick coating – are still completely intact.

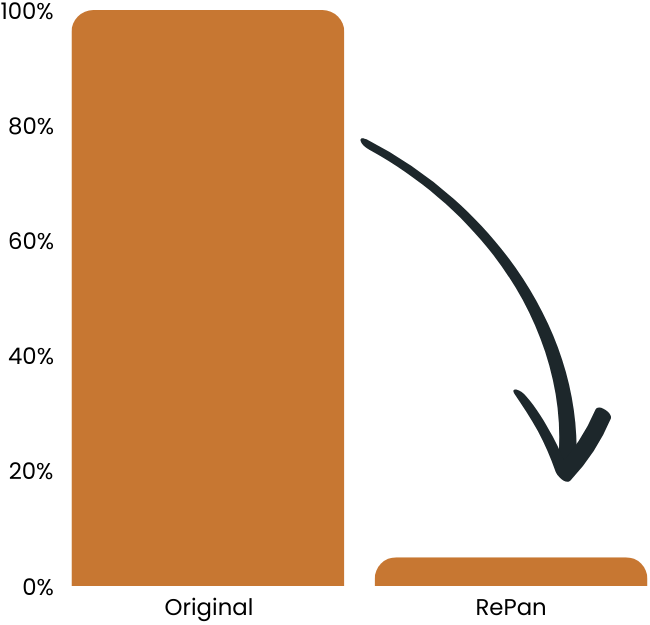

Save 80-95% resources with RePan

RePan focuses on regional sustainability. By upcycling intact pans from the region and reusing customer pans, we save resources and protect the environment. On the one hand, we sort out intact and high-quality pans that have been disposed of in the recycling station together with waste disposal centers such as those in the city of Zurich. Secondly, we accept our customers’ pans so that they do not have to be disposed of unnecessarily.

*Source: Tefal LCA “livre vert”, life cycle analysis calculated by Quantis in Lausanne and ENSAM laboratories. To make a Virgine pan comparable to a newly coated one, RePan adjusted the calculation to the new coating and excluded the use phase of the cooker. The range is due to the fact that factors such as the origin of the original pan and the perspective between resources, ecosystem, health and global warming can change. 80-95% or a factor of 5-20 is huge! Where else can you get such a much lower footprint with a better product?

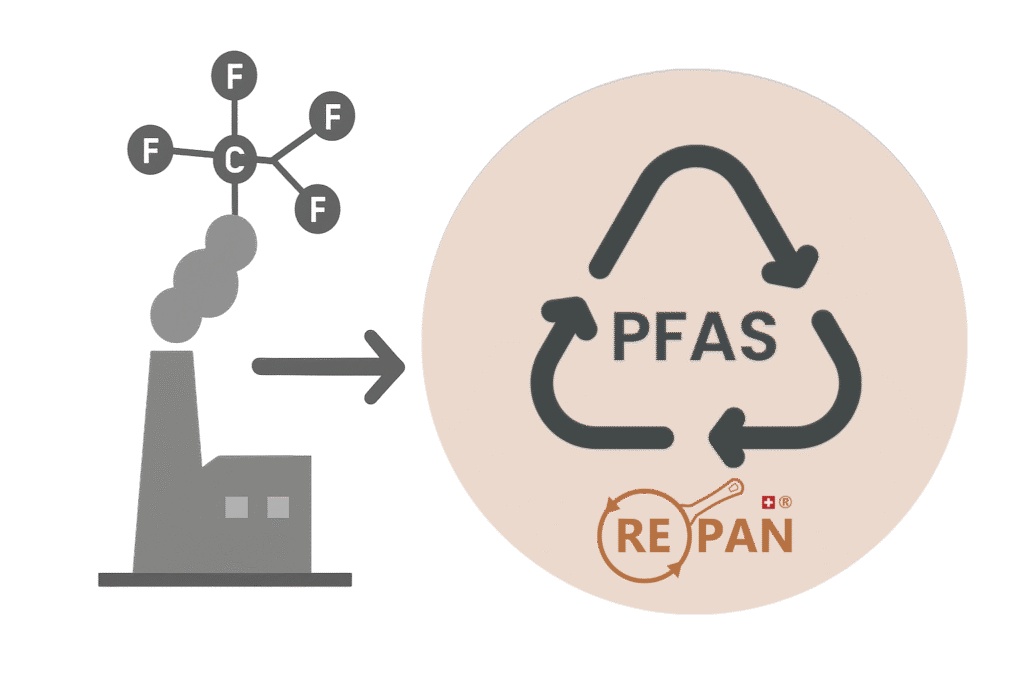

PFAS correctly handled

Per- and poly-fluorinated substances, molecules with fluorine atoms to put it casually, are currently on everyone’s lips. This is a huge group of substances that are very long-lived – and therefore degrade poorly in nature.

Nowadays, the pans are melted down at the end of their life and are released into the environment via the chimney. At RePan, we do things differently: we remove the old coatings mechanically, blow them out of the corundum and incinerate them in special waste incineration plants.

But isn't Teflon toxic?

No. Find out why this is a myth

Mining is particularly problematic

As we still need to cook and eat despite disposing of pans, they are usually replaced by new pans.

This avoidable consumption goes hand in hand with energy-intensive and environmentally harmful production.

Mining is particularly problematic in this respect, as mountains are perforated and removed in order to extract the metals from which the pans are made.

By devastating entire landscapes, mining disturbs the habitats of many animals and plants.

Metal extraction also has catastrophic consequences for people.

Metal processing requires many resources

In addition to the actual tunnels, the processing of metals is one of the dirtiest industries of all. In addition to the oil-powered machine bodies, transporters and smelting plants, the reduction of ores releases a wide variety of toxic waste such as sulphur dioxide, heavy metals, acids and alkalis as well as particulate matter. These pollute the air and get into the groundwater, which in turn damages people’s health.

Recycling is good, but not enough

Statistics show that currently 30% of metals come from recycling. But why is that not enough? Even if metals are actually imperishable, they are often disposed of prematurely because they rust or deform. The mountains of old metal have to be collected, transported, separated, chemically treated, melted, alloyed, shaped and cut in order to be processed into new products.

Although this process requires less energy than mining, it still accounts for a considerable proportion of the 4.4 billion tons of CO2 emissions worldwide every year. To reduce the environmental impact, we need to improve recycling and reuse worn-out products instead of wasting them

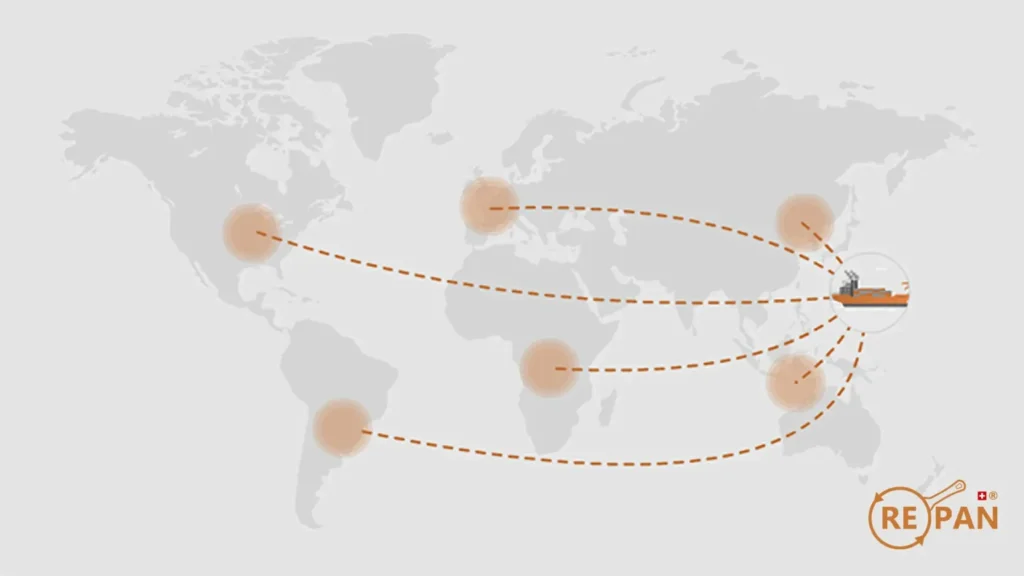

Globally unnecessary nonsense

In addition to the aforementioned problems associated with the manufacture of pans, there are other problematic practices. As the mines are located around the globe and commercially available pans are usually produced in Asia, the pans are transported long distances before they find their way into Swiss kitchens. The production and transportation of pans is therefore very energy- and CO2-intensive overall. Against the backdrop of global warming and dwindling resources, this is a real challenge that we want to take on. We prefer to think globally, but act as locally as possible.

Sustainable Packaging

As you can see, RePan avoids the problematic activities of above. But that’s not all!

Our reusable logistics also uses reusable containers: instead of disposable cardboard, we use plastic crates that we can reuse dozens of times. And as the icing on the cake, we use discarded cardboard from trade and industry to produce padding material.

Our offers

Newly coated from stock

-

If you send in pans, they will be missing at home. That's why we sell newly coated pans from stock!

-

Choose, order & return old ones

-

400 different pan models from stock

-

Cheaper or more durable than original

Recoat your own

-

All brands, shapes, sizes & materials

-

Convenient pick-up anywhere in Switzerland

-

Ceramic-reinforced gastro coating - free from PFOA, APEO, GenX & BPA.