Pan knowledge

Cheap goods are systematically sorted out, repairs are applied sensibly and the best and most durable non-stick coating we can find is applied.

Roller Coating

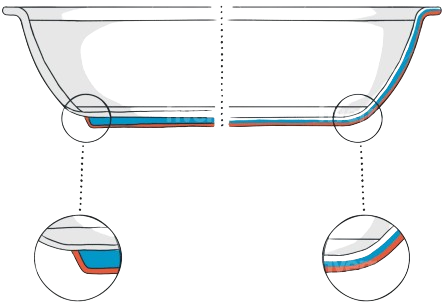

Roller coating is a process in which a coating is applied to a surface using a roller application process. This process is very inexpensive, but also leads to short-lived results, as the coating is compressed.

Curtain Coating

Curtain coatings are applied to the metal sheets using a spray process, from which the metal blanks are subsequently punched out. These in turn are formed into frying pans together with the coating. The disadvantage is also that the coating is compressed.

Spray coating

RePan uses spray coating. The key difference is that these coatings are applied to ready-molded frying pans. The advantage of this type of coating is the homogeneous coating with closed edges. The coating is not compressed and therefore offers a long-lasting coating.

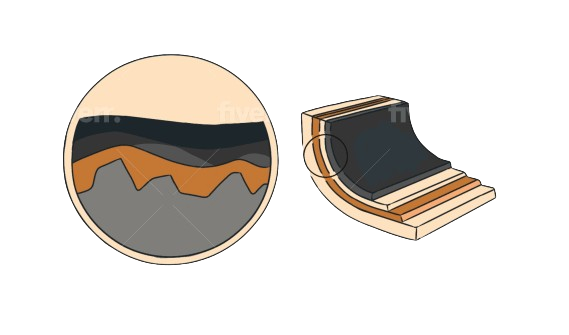

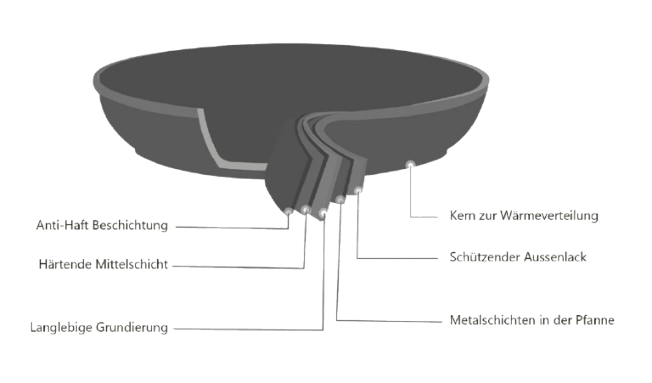

Materials and their structure

Choosing the right frying pan can make the difference between a successful meal and a culinary disaster. A modern frying pan is characterized by its material composition. The bottom consists of three layers that are perfectly coordinated. An aluminum layer ensures effective heat transfer from the stove to the pan, while a magnetic core can be heated on an induction hob. Chrome-nickel steel is used for the pan body to ensure optimum acid resistance. This high-quality material meets perfect workmanship, resulting in the so-called sandwich base.

But it gets even better: to further improve the quality of the frying pan, the multi-layer structure is also raised on the walls. This distributes the heat more evenly over the entire frying pan body and increases the surface area that can be induced on induction hobs. This means that the Multiply frying pan not only heats up faster, but can also be regulated more precisely. This makes frying child’s play and guarantees perfect results.

Pan handles

Did you know what a “flame guard” is or that a metal handle is always hollow on the inside?

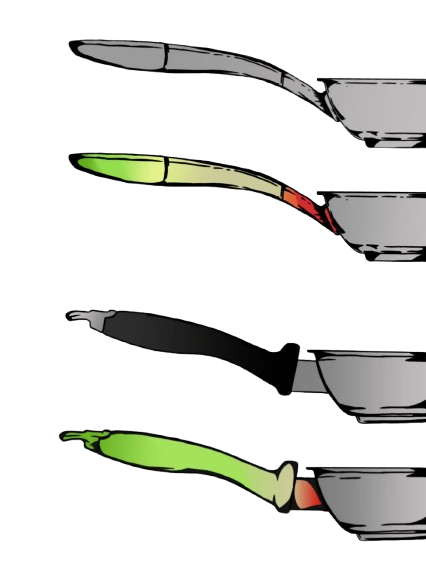

The handle is an integral part of the frying pan. All too often it starts to wobble, bend or melt. Care should also be taken with the protruding part, as it should be durable, not get hot, be ovenproof if necessary, protect against fire and flame and simply allow the pan to sit comfortably in the hand. This is basically done using two methods:

Plastic, wood or bamboo handles are screwed to the pan itself with a hollow metal piece. This reduces heat conduction and, above all, prevents fire on gas stoves! However, this is often disregarded during cleaning and deserves a polish at RePan for this very reason.

Metal handles usually last longer, but the material conducts heat very readily. But we don’t want them on the hand, which is why they are hollow on the inside, at least in parts. The assembly is usually a complete rivet, but we are happy to tighten it again after a pan’s life.

Well then, don’t let anything burn!

We take note:

There is a lot of knowledge, design and valuable material in pans. Let’s preserve it and refine it with the best quality with RePan.

Newly coated pans can be at least as good as new ones, sometimes even better.

In addition to the quality of the pans, the advantage of RePan is the regional added value and the massively lower consumption of resources, as the materials do not even have to be shredded, melted and reshaped.